March 19, 2021

FAQs About Septic Tank Aerators

If you’ve recently moved into a home with an aeration system or aerated septic tank, or are looking to install a new ATU to repair your current septic system, then you might be looking for answers about septic tank aerators.

If you’ve recently moved into a home with an aeration system or aerated septic tank, or are looking to install a new ATU to repair your current septic system, then you might be looking for answers about septic tank aerators.

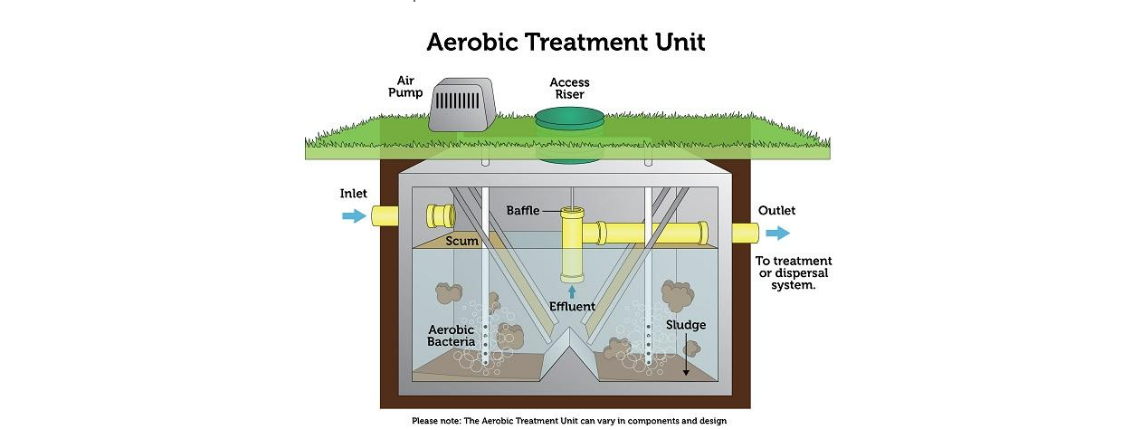

An aerated septic system goes by many different names, depending on the state where you live: Aerobic Treatment Unit (ATU), aeration system, septic aerator, advanced onsite treatment unit, etc. All these are names for proprietary wastewater treatment units that have been approved by some regulatory body and use an air pump or other mechanism to inject air into the tank holding the wastewater.

Often, the septic tank aerator is the only moving part in the system. It is the true heart of the system, keeping your wastewater treated and your drainfield protected. So, you want to ensure it’s always running smoothly and is well maintained.

Keep reading for our septic aerator FAQs:

- What exactly is a septic tank aerator? An aerator, or air pump, pushes air and oxygen into your septic system. The additional oxygen increases natural bacterial activity within the system, that then provides additional treatment for nutrients in the effluent. An aerator system draws air in from the outside and pumps it through a piping network and diffuser that is inside the tank.

- What are the benefits of a septic aerator? The benefits of this system are that it can be used in homes with smaller lots, inadequate soil conditions, in areas where the water table is too high, or for homes close to a surface water body sensitive to contamination by nutrients contained in wastewater effluent. Regular life-time maintenance should be expected for ATUs.

- How hard is a septic tank aeration system to maintain? You still need to pump your tank every 3-5 years, as normal for any onsite septic system. Always be mindful of what you send into the tank with an aeration system—a great guide is the Think at the Sink brochure from EPA SepticSmart program. You also will need to repair or replace your aerator as the moving parts reach the end of their service life. Always make sure you are using genuine factory certified parts for any repairs, as aftermarket parts will void any warranties and may not handle the pressures of your overall system. The lifespan of your aerator will vary based on the size, the outdoor temperature in the region where you live, whether your in-tank diffusers need to be cleaned, and how your pump is installed.

- Which HIBLOW air pump do I need for my septic system? Please contact the manufacturer of your overall treatment system to ensure the correct sizing of the air pump for your specific unit. A professional service provider may also be able to determine the HIBLOW pump model you need.

- Where can I purchase repair kits for my air pump? We have numerous distributors across North America that can supply you with both pumps and repair parts. Please email or call for your closest or most convenient option. Make sure you are using genuine factory certified parts. Aftermarket parts will alter the performance of your air pump and it may not be reaching the pressures required for your system.

Author: Tim Smith

Contact HIBLOW for Septic Aerators!

With the help of our HIBLOW aerators, wastewater systems serving homes and businesses are ensuring that only treated water is entering the environment.

Thanks for the reminder that the bacterial balance should also be considered when planning to get septic maintenance. I’d like to find a good septic pump service soon because I’m thinking about getting some plumbing upgrades for my home. I think that will also be a good time to get my septic system pumped.

What is the ideal level of the liquid in the septic tank to turn on the air pump after cleaning out the tank?

Great question! The alarm will sound when the water is less than 1 PSI. 2.31 feet of water depth equates to 1 PSI. Therefore, you probably don’t want to turn the aerator on until the water level returns to ~2.5′.

In your experience, are air pumps required to be switched off when pumping out septic system and left off until system is refilled?

We hear conflicting stories. Thank you.

Hi Daniel – I’m not sure if it is required, but I think it would be logical to unplug the pump or turn off the breaker to the panel before pumping. If you keep it on the alarm could go off because of the low water level. The aeration process could stir up solids as well.

Does The aerator shaft need to be submerged to test the unit?

What is the most common part that breaks?

The shaft on mine won’t spin unless you manually turn it to get it started. Could that be the capacitor? Is this a common part that breaks?

HIBLOW manufacturers a linear diaphragm air pump. I’d suggest contacting the OEM of your aerobic system who will have a much better understanding of the shaft aerator technology. Aerobic service professionals in your area may also be able to assist.

I appreciate it when you explained that aeration systems for wastewater treatments will be pushing air and oxygen into the septic tank which will increase the natural bacteria activity and provide nutrients in the effluent.

Should the aerator run 24/7 or can it be put on a simple adjustable on/off timer to reduce electricity usage.

Really good question. You should run the aerator as directed by the manufacturer of the aerobic system. With that said, it is unusual for the pump to NOT run 24/7, 365. The system needs the oxygen to feed the beneficial bacteria to eat away at the waste before it enters the drain field. That beneficial bacteria also is flushed into the field to reduce and prevent biomat which extends the life of your field. Most HIBLOW models run on 75 watts or less – which is equivalent to an incandescent light bulb.

The alarm sounded on my aerator and I had to shut it off. I inspected it and there is nothing on the shaft. It had just been serviced in the last 6 weeks.

How long can I go without it running while I await a new pump (which I think is the problem)? Is a few days without it ok?

You want to be back up and running as quick as you can, but it should be ok if you are down for a few days. I would like to try and help you troubleshoot your pump. Feel free to email us at info@hiblow-usa.com or you respond on here too. How old is the pump? The first 4 digits of the serial number is the date code. Have you ever rebuilt the pump? We suggest doing that twice before buying a new one. Did you check the diaphragms? There is a rebuild video on our website under the support tab if you need help accessing the diaphragms. Hopefully we can help you fix the pump so you don’t have to spend the money for a new one.

Thank you for your help. The serial number begins 9201….Singulair by? Norweco? Model 206C.

Is 9201 indicating 01 of 1992?

Leslie – I’m going to email you directly.

I live in the interior of BC in the Penticton area. In the fall I replaced the diaphragms in my Hiblow HP-80-0110 Aerator and everything was working normally until a few days ago after several -20C days 2 weeks ago. The alarm went off and I checked the diaphragms. They are intact. The float in the Aerator tank is fine and water is flowing through from the septic tank. What parts are outside near the tank that may be at fault?

A few possibilities: 1) If there is an external alarm and a 1/8″ clear tube is connected to a barb on our pump (that runs to the alarm), it is fairly common for condensation to get into that tube and block the external alarm sensor from sensing the pressure. 2) There are other alarms for many other things on the system. It could be the water pump. 3) A PVC fitting underground or at the connection of the tank could have broken. Sometimes when the ground freezes it can heave up which can cause this. 4) If only the diaphragms were replaced and not the casing blocks that have the valves, the valves could fail which would make the pump lose pressure. With regards 3 and 4, you can rule them out by peering into the aerobic tank to see if there are bubbles. If there are not any bubbles, then pull off the L tube from the outlet of the port and see if air is coming out. If it is coming out, then you probably have a break in the line, if it isn’t, the pump is losing pressure assuming its still running. The pump itself is not impacted by cold weather because it produces heat since it’s running 24/7. Please advise if you have any other questions.

A pump was installed right next to our bedroom window. We can hear it running and it disrupts our sleep. Will it hurt to shut it off about 6-8 hours?

Aerators in aerobic systems are typically meant to run 24/7, 365. Turning the pump off for 8 hours wouldn’t be good for the system. You may want to consider having your service provider move the air pump to a different location that isn’t next to the bedroom.

I just installed an XP-80 for my Septic System. When the pump is on my system backs up. When off the system operates normally (toilets flush normally). I opened the sewage cleanout and with the air pump on water from the sewage system flows out of the cleanout. With the air pump off there is no flow through the cleanout and there is very little water in the piping. Is the XP-80 too big for my system (do I need an XP-40) or is my septic tank too full (last pumped out was over 5 years ago)? All indication when purchased was that the XP-80 was not too big. My house is 3100 square feet but I do not know the size of my septic tank. Thank You!

Sorry for the delay- your message was lost in spam. Did you resolve the issue? If yes, do you mind sharing with the group? I would have directed you to a service professional. Sounds like you probably need your tank pumped, but it could be something else too. Out of curiosity, what size air pump did you have before you purchased the XP-80?

Can replacing an HP-60A pump with an HP-80A pump cause harm to the septic system.

Each system goes through extensive testing with a specific size air pump – in this case, the HP-60A. If you bump up to the HP-80A, you are increasing the air flow in the system by ~33%, which is currently out of the allowed range for an alternative blower. It would be our suggestion to either rebuild the HP-60A or buy the HP-60A, but you could contact the manufacturer of the system for their advice as well.

Should aerator pumps be installed above ground or below ground? What’s the best recommendation for system not to malfunction?

Thank you

HIBLOW aerators are installed above ground. They are rated for outdoor use, so they can withstand the elements, but they should not be submerged in water. Keep them shaded but allow for ample air circulation for best results. Make sure to stay within a reasonable operating pressure to maximize the life of the diaphragms.